Martin:

Sincere thanks for your quick and extremely helpful reply to my posting!

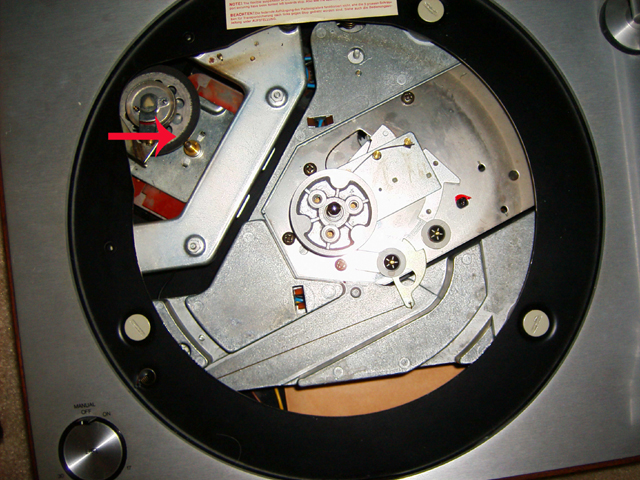

That worked beautifully! I had been reluctant to pull on the center tap, but once I knew that it was the key, a little persistence popped it off. The problem is clearly exposed: it seems that the cam wheel no longer makes contact with the shaft (arrow in the photo). I am guessing that the rubber has just worn down over its 30+ years of service.

Does this sound like a reasonable assumption?

Steve