Tools required:

thin blade / knife

fine tweezers

contact cleaner (e.g. servisol 10)

helping hands

fine nose pliers to replace circlip

Singer oil.

A trip to Maplin or other electronics store will be beneficial.

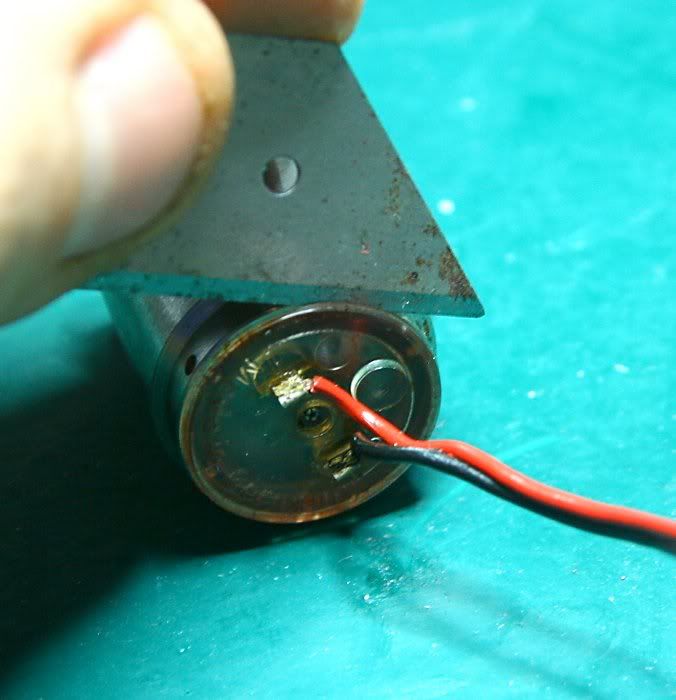

Firstly remove the back end carefully with a sharp knife. You are not

cutting but levering here - I normally move to the back of the

blade...

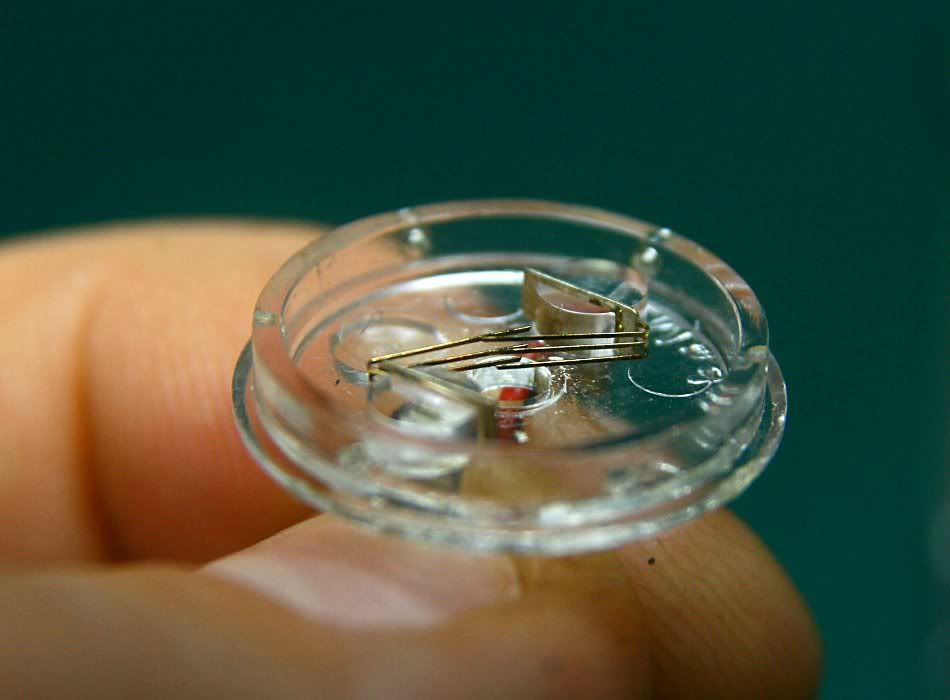

The brushes

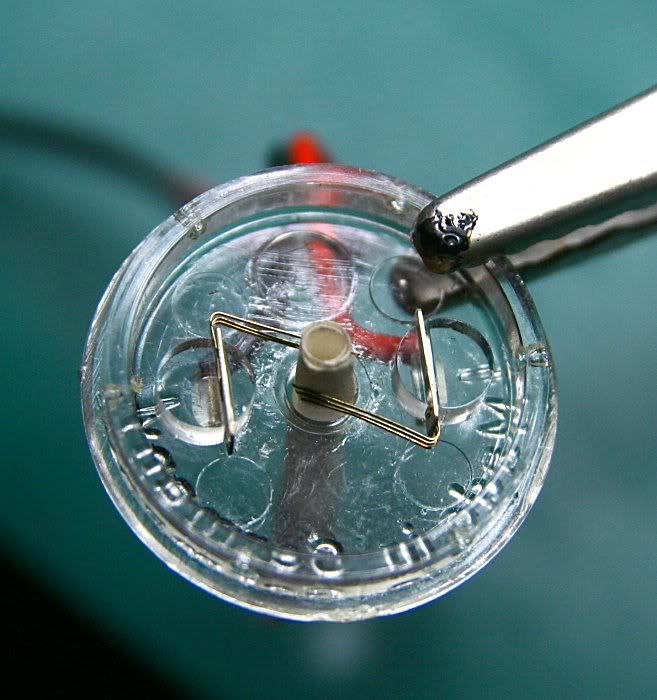

Remove the circlip and washers...

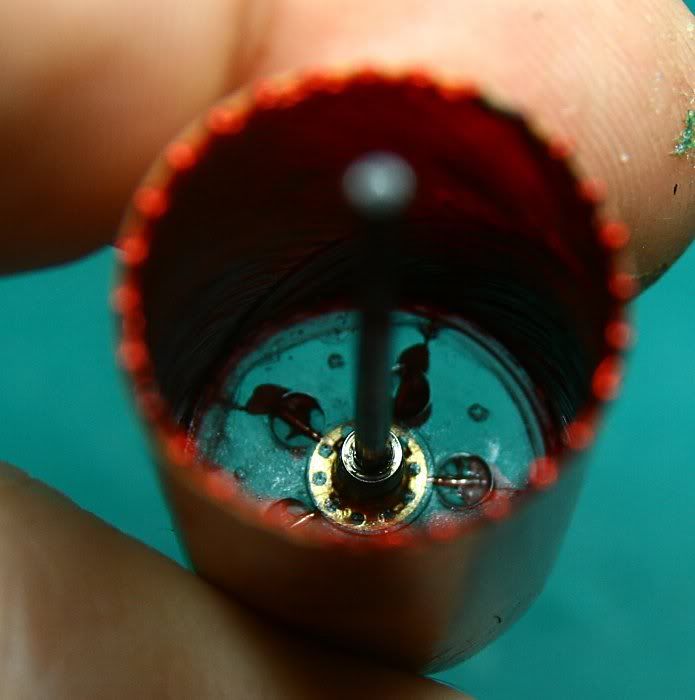

Front bearing to be relubed...

Rear Bearing to be relubed... Just visible but recessed.

The shaft - I normally give a clean and remove the washer at the bottom and clean this too. Then a dab of oil.

The

fidly bit - Reinsert the rotor into the motor body, making sure any washers are present. Add the one or two washers to the end and then line the circlip up with its groove in the motor shaft. Very carefully squeeze back on with pliars. Do this in such a manner that should the thing ping off it can't go far because finding one of them in the carpet is not fun!

The brushes will have likely crossed over. At this point use

some fine tweasers to reverse them and open them up. Then I have a

rolled peice of paper ready and insert from the rear through the access

hole. Release brushes and allow them to sit against the paper - whilst the paper is allowed to open up in the hole. This is a

good opertunity to spray contact cleaner onto the paper and clean the

brushes by rolling a few times not against but with the direction of the brushes.

Place rear plate back on the motor making sure to line the raised buts it should now click in place slowly revolving paper whilst you withdraw..

.

.

Simple job just a little fiddly - Take your time!

At this point I normally run for a while on my bench supply to establish everything is ok...

Edit to add a couple of bits of info...